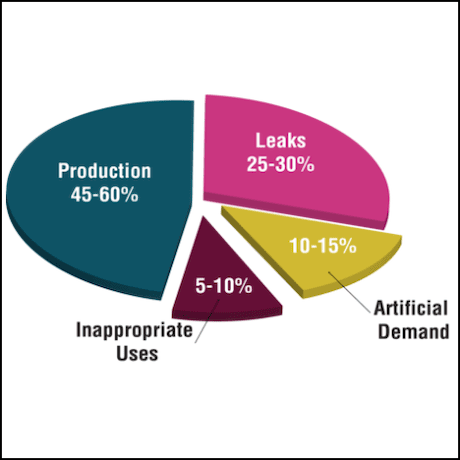

LEAKS: The most common issues found are leaks, studies from Kaeser Compressors suggest. Additionally, the U.S. Department of Energy estimates “As much as 25% of the compressed air produced in the market today is wasted to leaks, and everyone has leaks.” We can help you locate the leaks and perform the repair. Detection and following the recommendations provided from a professional audit will find these leaks, reduce the cost of energy to run your compressor, and save your investment in a compressor.

OVER-PRESSURIZATION: Increasing pressure to compensate for capacity issues makes any leaks, leak more and can increase power consumption by 5% for every 10 psi increase. We will help you determine your system is running and responding when required and lower the pressure of your compressed air system operating closer to the actual design requirement.

PIPING & CONNECTIONS: Piping is usually where most operators find needed improvements, that is why piping is also an important consideration! We look for piping restrictions, consider piping material, old layouts, wrong pipe sizing, pipe expanded sections due to company growth. You can easily identify a well laid out piping system should at first glance, understand and see where the pipes are going, why, and continue on to use. Compressed Air Systems, Inc would help ensure your actual piping system delivers the optimal required airflow and produce the minimum pressure drops. Check the angle of directional entry connections and discuss possible affordable replacement solutions for tee connections.

RESTRICTIONS: Service and maintenance schedule will help save you money by avoiding performance and air quality issues. Know your system, know where and what is in use, disconnect any unused systems. Some things that can impact capacity, performance and create air quality issues; filters with rust, scale or clogged, manual maintenance like drain traps and separator cartridges. Take advantage of the Compressed Air Systems, Inc regular maintenance services.

Double-check your checklist – find any improper applications – lack of compressor controls – ensure your operating systems is maintaining consistent stable pressure – confirm you have sufficient storage – advise – help to monitor and maintain – Venturi air nozzles – air inducers – pumps – diaphragm pumps

and much more…