Rotary screw air compressors rely on two interlocking rotors to generate compressed air, making them ideal for a wide variety of industrial applications. From powering air tools and packaging to inflating tires and spray painting, the compressed air produced by a rotary screw compressor is clean, quiet, and incredibly efficient.

Read on to learn more about rotary screw air compressors, including how they work and the compressors available at KAESER.

What is a Rotary Screw Air Compressor?

This type of air compressor uses two meshed rotors, male and female, to produce compressed air. The two rotors are also known as rotating screws. Rotary screw air compressors have become more popular in recent years than piston air compressors due to their durability, adaptability, and innovativeness. They are suited to a variety of industrial applications even when they are used continuously.

Rotary screw air compressors use a positive displacement mechanism to function. The screw air compressor uses two meshing rotors to trap and compress air. A dry-running rotary screw compressor uses timing gears, which ensure the two rotors are always aligned when they move and don’t come into contact. In an oil-injected rotary screw, lubricating oil is used to bridge the gap between the rotors, providing a seal and allowing the rotors to be driven by each other. The compressed air is used to power equipment in different industries, including manufacturing, food and beverages, and mining.

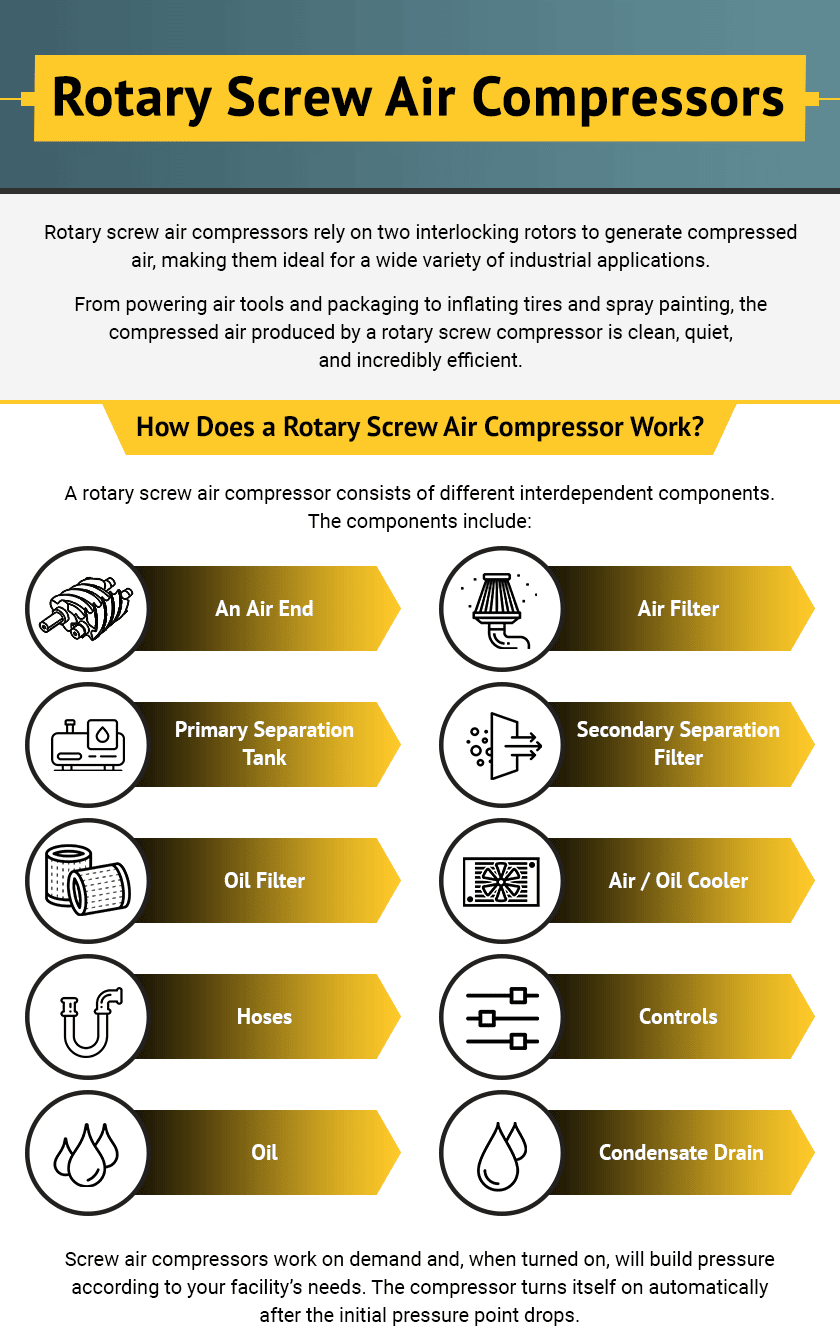

How Does a Rotary Screw Air Compressor Work?

A rotary screw air compressor consists of different interdependent components. The components include:

- An air end

- Air filter

- Primary separation tank

- Secondary separation filter

- Oil filter

- Oil cooler

- Hoses

- Controls

- Oil

- Encapsulated air end

Screw air compressors work on demand and, when turned on, will build pressure according to your facility’s needs. The compressor turns itself on automatically after the initial pressure point drops.

Operationally, a rotary screw air compressor requires both air and oil to function. Air enters through the suction side, while oil provides lubrication for the system. The two components highlight the compressor’s complex system, which produces compressed air and runs a lubrication process that keeps it operational.

Step-by-Step System Flow

- Air is sucked in through the inlet valve and flows to a regulator valve through the pressure system line that sets the pressure for the system.

- The air is mixed with oil and compressed through the male and female rotors in the air end.

- The air and oil mixture exits the air end and enters the primary oil separator tank, where the oil and air will be separated.

- Air enters the secondary separation filter, and any remaining oil is filtered.

- Air exits the system while the oil is moved into the oil cooler, cooled down, and then sent to an oil filter.

- The filter traps any debris remaining in the oil, which is then returned to the air end through the scavenge return line.

Our Rotary Screw Air Compressors

When it comes to powering production processes, a reliable supply of quality compressed air is essential. That’s why rotary screw air compressors are so popular in countless industrial, trade, and workshop applications. These machines are ideal for applications where a constant pressure supply is needed for prolonged durations.

At KAESER, we understand the importance of efficiency. That’s why we developed our own special rotor profile — the SIGMA profile. Our compressors feature a design that enables them to deliver energy savings of up to 15% when compared to other traditional rotor profile designs.

To further enhance the reliability and longevity of our compressors, we use precision-machined and generously sized roller bearings in our SIGMA profile air ends. This helps ensure an exceptionally long service life, allowing our customers to get the most out of their investment.

At KAESER, we take quality seriously. Our state-of-the-art, in-house manufacturing processes and strict manufacturing tolerances allow us to deliver the exceptional level of quality that our name is known for. So when you choose a rotary screw compressor from KAESER, you can count on quality you can trust.

Upgrade Your Compressed Air System with KAESER’s Rotary Screw Air Compressors

Screw compressors are the preferred choice for efficiency, durability, and innovation in high-powered industries like mechanical, mining, transport, food, and health. KAESER has been a leading producer of compressed air systems for over a century, specializing in tailor-made, energy-efficient, and reliable solutions. We aim for optimal availability and cost-effectiveness, providing exceptional customer service and support. Contact us or request a quote to find the perfect compressed air solution.