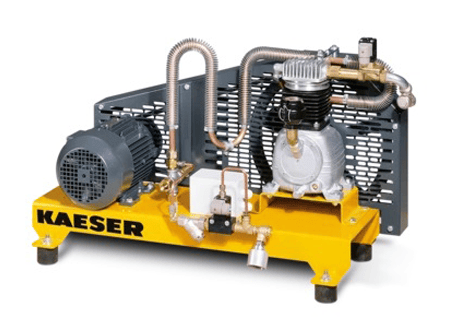

Booster Air Compressors

While commercial and industrial compressed air systems usually support pressures between 90 and 125 psig, certain applications depend on higher-pressure airflow. Leak testing, printing, and plastic molding are just a few examples of processes that utilize high-pressure air, and operations can achieve the necessary air supply and pressure with the aid of a booster air compressor.

Also referred to as air compressor boosters, these systems are an economical means of successfully boosting pressure and flow rates, especially compared to installing a higher-capacity compressor or wasting resources running a facility at higher levels than necessary. Installing a booster that is rightsized for your specific application offers higher efficiency.

At BuyKaeser, we supply an array of compressed air solutions to fulfill diverse needs. Learn more about how booster air compressors function, their applications, and why to use them.

Booster Air Compressors: How They Work

Booster air compressors are always used in conjunction with a standard air compressor. The regular air compressor takes in ambient air and compresses it to low pressure levels, and then the booster increases the inlet pressure to medium or high levels. Both types of compressors, however, follow the same fundamental principle: air volume decreases in proportion to the increase in pressure within a closed, non-vacuum system.

Available in oil-injection and oilless varieties for optimal air quality, booster air compressor systems are made up of several main components, such as:

- Pistons

- Pumps

- Receiver tanks

- Piping

- Discharge tanks

Most booster air compressors rely on a specially designed piston for efficient pressure management and upstream air usage. Its block and cylinder are made in diameters capable of handling the high pressure. A single- or multistage pump assists in effectively compressing the air.

The primary feed of compressed process air passes into a receiver tank through its inlet, at which time the tank further compresses the air as part of a multistage process until it reaches the necessary discharge pressure level. When not actively providing air to the discharge tank, the receiver tank can also provide compressed air storage.

Air Compressor Booster Pressures and Applications

Air compressor boosters have the capacity to fulfill a wide range of industrial applications, which often involve pressures between 80 and 150 psi. Medium-pressure systems typically utilize a 20- to 40-bar booster, whereas high-pressure applications might require a booster for 200 to 350 bars of pressure.

Medium-Pressure Applications

If a system’s air consumption is consistent, 40-bar air booster compressors can offer good on-demand supply. Examples of medium-pressure applications include:

- Industrial cleaning projects

- Industrial stress testing

- PET bottle manufacturing and blowing

High-Pressure Applications

Systems that may experience spikes in demand and require highly pressurized cylinders for sufficient operations, however, need a high-pressure booster. A 300-bar booster is ideal for:

- Cylinder filling

- Industrial pressure testing

- Plastic molding and forming

- Laser cutting

- Metallurgical applications

- Oil and gas handling

Air Compressor Boosters vs. Air Compressors

If your operation requires a reliable air supply at pressures that exceed your compressor’s capabilities, adding a booster is an optimal choice. As discussed, air compressors and boosters typically work in tandem to fulfill high-pressure air supply needs. For example, a screw compressor on its own can successfully compress air when it’s supplied at 0 psig or 14.5 psia. To achieve greater pressure, however, you would need to add a booster.

Without a booster, operations do have the option to purchase and utilize a standalone high-pressure compressor, but this can be quite expensive and typically offers less versatility than combining a standard compressor with a booster. Air compressor boosters can capitalize on your facility’s existing air system, further compressing the air to the desired outlet pressure, and address location-specific requirements with a high degree of efficiency.

High-Pressure Booster Air Compressors From BuyKaeser

Specializing in compressed air technologies like booster air compressors, BuyKaeser supports the needs of numerous industries looking to affordably scale their compressed air capacities. As Florida’s premier distributor of compressed air systems and components, we also provide compressed air leak audit and detection program services, maintenance and repair services, and equipment rentals for comprehensive air supply solutions.

Contact us to learn more about enhancing your facility’s ability to generate high-pressure compressed air, or request a quote today to get started.